3D scanning, inspection, and reverse engineering services in the greater Seattle area

Serving the Puget Sound area since 2021, Sentinel 3D Scanning seeks to empower product developers with timely and accurate 3D data. Our 3D scanning services provide accurate mesh files for use downstream, our dimensional inspection services help to ensure your product’s quality, and our reverse engineering services enable you to begin your design process with confidence.

At Sentinel 3D Scanning, we strive to provide accurate, repeatable data in a timely manner and at a competitive price. Whether you are looking for a metrology lab to outsource your company’s inspection projects to, or an individual with a passion project, we can help you meet your goals.

High Accuracy 3D Scanning Services with Quick Turnaround Times

Looking for 3D scanning services in Seattle? Look no further than Sentinel 3D Scanning! Allow our 3D scanning services to be the catalyst that moves your project forward, enabling rapid prototyping, accurate CAD models, and ensuring product quality.

Accurate 3D scan data begins with high quality equipment and subject matter expertise. Settling for 3D scan data that lacks either of these two attributes can result in serious consequences down the line, like failed products, scrap, or wasted time. Sentinel 3D Scanning’s metrology-grade 3D scanners, years of experience, and industry certifications fulfill both requirements, resulting in high-quality data you can trust.

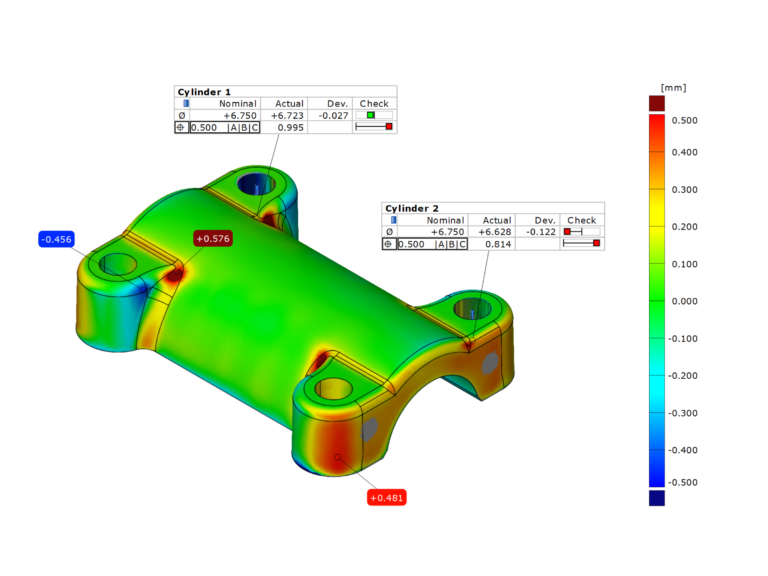

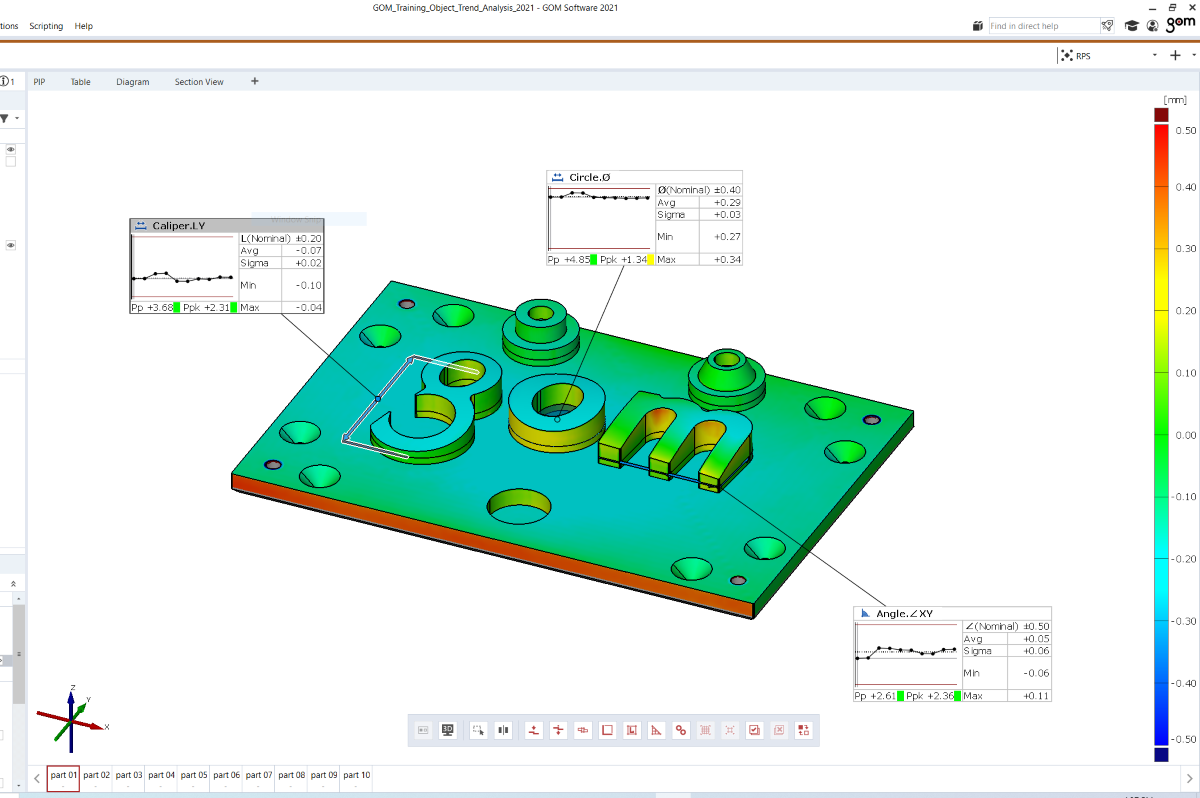

Improve Product Quality with Dimensional Inspection Services

Do you have prototypes or production parts in need of inspection, but lack the necessary resources or internal metrology lab to inspect them? Are you looking for 3D dimensional inspection services in Seattle, Washington? Outsourcing your inspection and quality control tasks can save you money by reducing training, equipment, and operational expenses. It can also open the door to new inspection technologies and expertise currently unavailable within your own organization.

Sentinel 3D is passionate about precision. At the data acquisition stage, we use high-accuracy, metrology-grade 3D scanners to collect measured data. And when analyzing measured data, we use software capable of inspecting ASME and ISO GD&T, while also recognizing its shortcomings. Additionally, lab personnel are certified by industry-recognized organizations to ensure the measurement uncertainty is minimized.

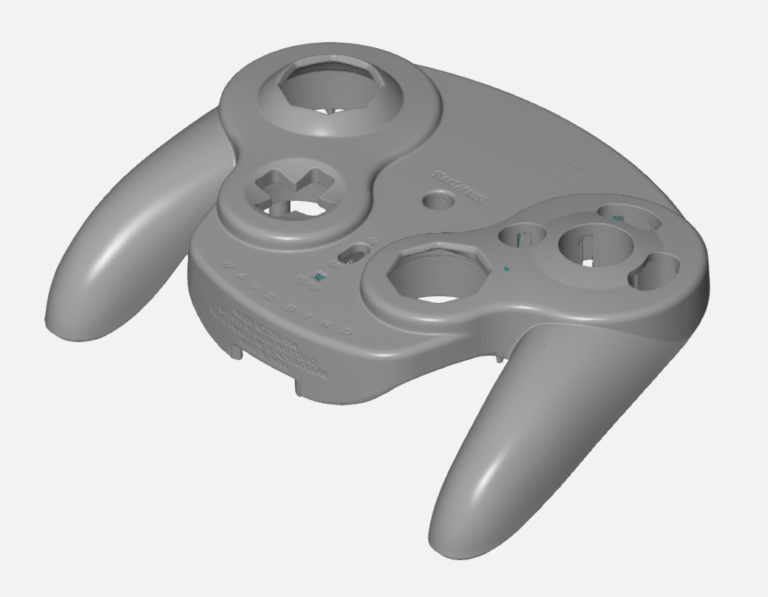

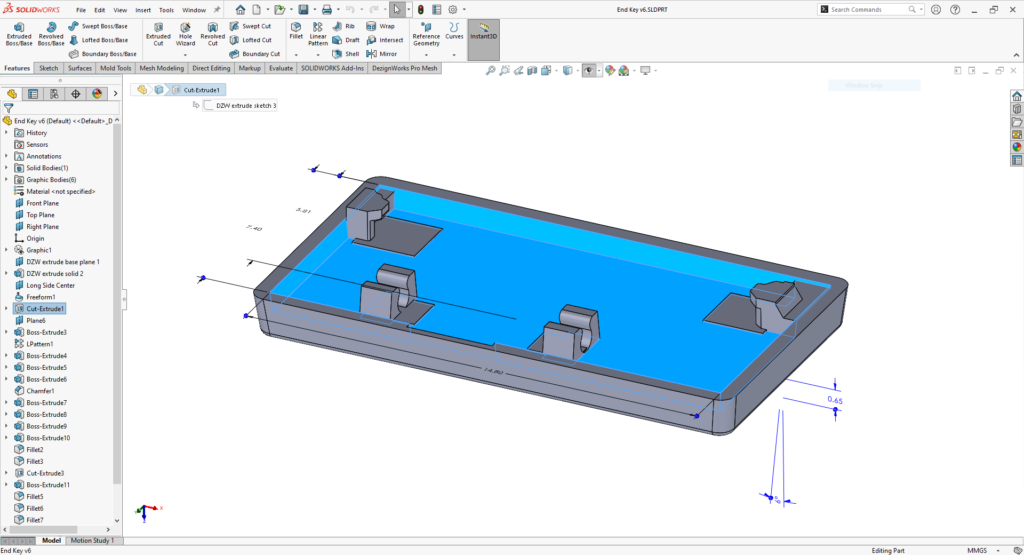

Reverse Engineering Services for engineers and hobbyists

In need of a CAD model that is not available? Sentinel 3D’s reverse engineering service can provide you with an accurate 3D model of your part or assembly so that you can get started on your project sooner. Applications include reproductions, design modifications, aftermarket parts, and finite element analysis.

We begin our reverse engineering process with accurate 3D data collected with metrology-grade 3D scanners. CAD models can be recreated in a variety of formats, balancing cost and editability. Once the CAD model is complete, its accuracy is checked against the original 3D scan data to ensure it will meet your functional requirements.

Sentinel 3D Scanning's Process

Initial Discussion

Before a project begins, an initial conversation needs to happen to fully understand the project’s requirements. This conversation can be had via email, on the phone, or in a video call. More complex dimensional inspection projects may require multiple conversations, and additional time to review drawings.

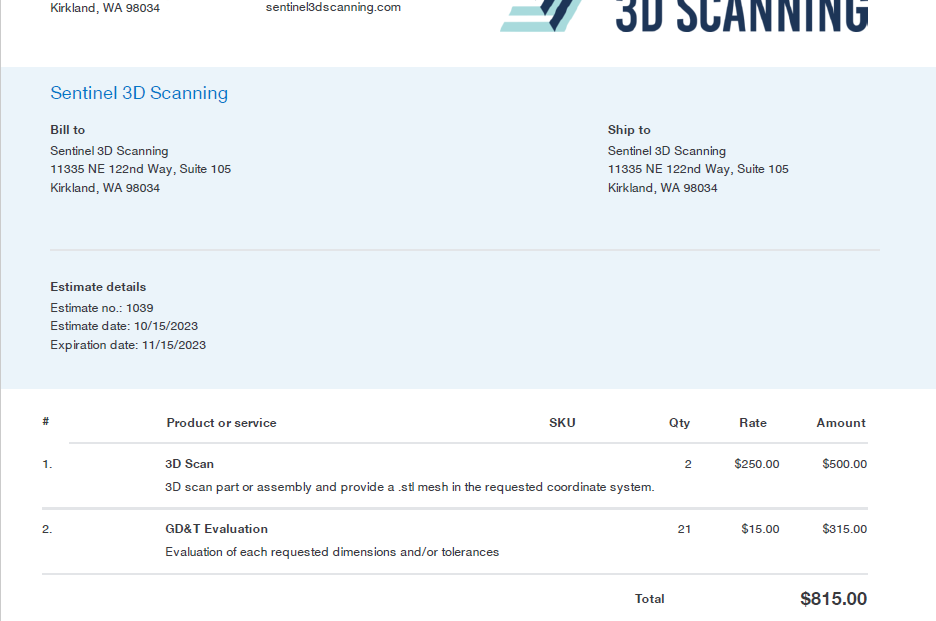

Estimate Review

Once a project’s requirements are well understood, an estimate will be provided. You then have the option to approve the estimate prior to moving forward with the project.

Sample Delivery

If the estimate is approved, the samples to be inspected can be delivered. If local to the Seattle area, parts can be delivered in person. Otherwise, parts and assemblies can be shipped to us using your preferred shipping method.

Data Acquisition

If the estimate is approved, the samples to be inspected can be delivered. If local to the Seattle area, parts can be delivered in person. Otherwise, parts and assemblies can be shipped to us using your preferred shipping method.

Data Processing or Analysis

The scan data is imported into analysis or modelling software for further inspection or modelling tasks.

Data Delivery and Review

The inspections results are delivered for your review. If necessary, a video call can be scheduled to discuss the results in greater detail.

Review and Pay Invoice

The invoice is sent via email and can be paid online. Payment options include debit cards, credit cards, and ACH payments.

Sample Return

The samples are returned either in person or using your preferred shipping method.

What our Customers Say about Sentinel 3D Scanning

The scanning he did for my car’s headlight mounts was very helpful in getting my engineering project started. Timely, accurate, and focused on detail.

Sean D.

Sentinel did an excellent job for us. Adam honestly explained his capabilities and delivered exactly as promised. The service and delivered data provided was precisely what we needed and in a timely manner. The costs were reasonable and we plan on using him again in the future.

Tony V.

Adam did a great job scanning for us. His knowledge and expertise was just what we needed.

Marcus B.